| Total Tank Volume |

700 bu |

24667 l |

| #1 Tank Volume |

370 bu |

13038 l |

| #2 Tank Volume |

95 bu |

3348 l |

| #3 Tank Volume |

30 bu |

1057 l |

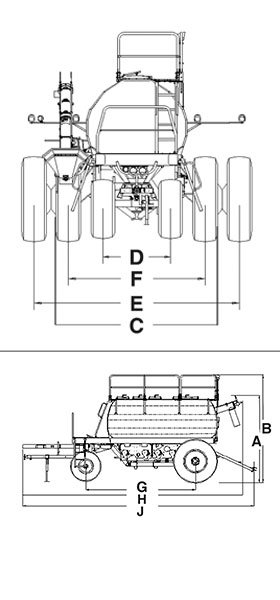

| A. Height - Transport (Top of L/U Agr/Cnvr) |

12' 2" |

3.7 m |

| B. Height - Field (Top of Hand Rail) |

15' 0" |

4.6 m |

| C. Overall Width (Single Tires) |

17' 9" |

5.4 m |

| G. Front Axle to Rear Axle (TBHD Only) |

22' 10" |

7 m |

| H. Length - Hitch Pin to L/U Auger/Conveyor |

40' 11" |

12.5 m |

| J. Length - Hitch Pin to Rear Tow Hitch Pin |

42' 3" |

12.9 m |

| D. Front Tire Spacings |

10' 4" |

3.1 m |

| Rear Tire Spacings, Single |

N/A |

N/A |

| F. Rear Tire Spacings, Inside Dual |

10' 0" |

3 m |

| E. Rear Tire Spacings, Outside Dual |

15' 0" |

4.6 m |

| Weight, Empty (Single Tires) *** |

22500 lb |

10206 kg |

| Load/Unloading Augers/Conveyor |

10" (25 cm) Conveyor |

|

| L/U Auger/Conveyor Load Rate (max.) |

110 bu/min |

3876 l/min |

*** All Units weighed with a L/U Auger or Conveyor